An Vacuum casting Sheet Essentials

Being a unprocessed materials, vacuum casting is available in a range of harnesses, densities and stiffness’s, but TPU vacuum casting bedding are specially manufactured to provide good quality abrasion, corrosion and impact level of resistance. According to the Worldwide Connection of Plastics Syndication (IAPD), vacuum casting very first got into lifestyle around 75 years ago on account of the efforts of a single Otto Bayer. Bayer with his fantastic staff got the TPU ball rolling, however the activities of World War II avoided vacuum casting sheeting from being commercially made till the earlier 1950s. That’s as soon as the key vacuum casting athletes like DuPont and Dow joined the scene. Given that that point, the vacuum casting modern technology made a great progress way, stretching out into a variety of software. In fact, the IAPD details to a variety of marketplaces for TPU page. They are the vehicle market, the aerospace business, the electronic products market, the protection sector, the energy presses / passes away business, the exploration business, the material coping with market, the steel concluding sector, the oils and petrol sector, as well as the railroad industry.

The connection then cites a number of the particular purposes of vacuum casting modern technology in every one of these market sectors. What follows can be a talk of some of these software. Within the railroad industry, railroad cars have arc shields that are made from vacuum casting page. The application of it results in much less breakages plus a much longer lifespan, thus lowering the railroad’s maintenance charges. Vacuum casting sheet can be used as a substitute for vacuum casting rubberized in gaskets and seals, affording such niche apps unmatched toughness and strong substance amount of resistance. What’s much more, vacuum casting provides for the reduced expense tooling of custom made closes.

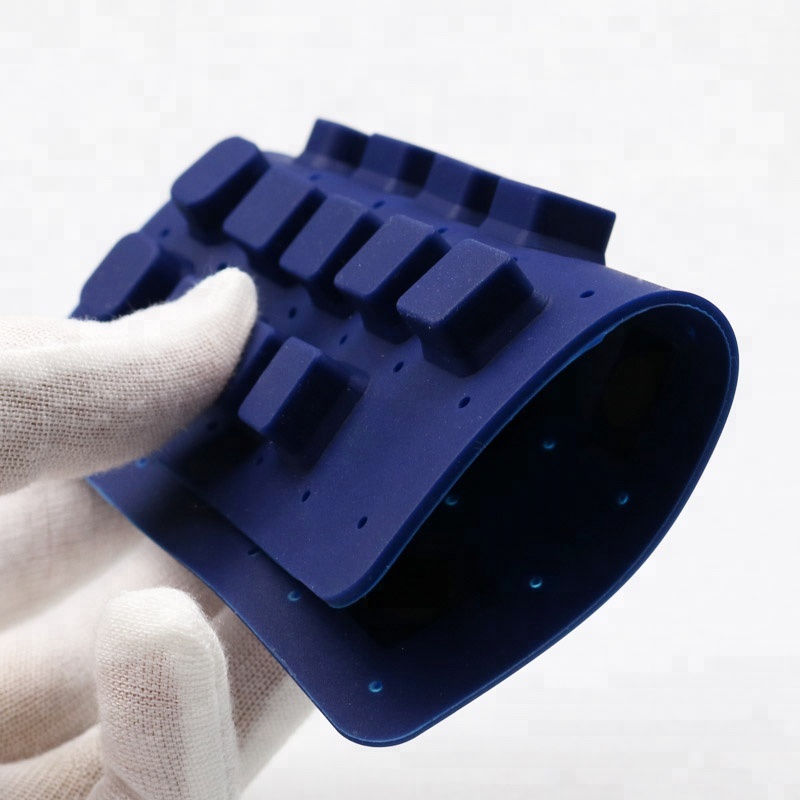

In the auto business, these bedding may be used instead of silicone for cart and trolley tires. They are also employed to line bins, tanks, hoppers and truck mattresses. To salary battle up against the high-impact and harsh deterioration the mining and materials handling businesses cause, vacuum casting bedding supply unrivaled benefits. They are often effortlessly put in due to their overall flexibility and light weight. As well, they may quickly stand up to the abrasion, corrosion, impact and temperature modify situations these market sectors need.